HOME / R&D / Inventing technology / FCVA

FCVA

FCVA (Filtered Cathodic Vacuum Arc)

- The Filtered Cathodic Vacuum Arc is a technology that uses arc discharge to evaporate the material and deposit it on the surface of the product.

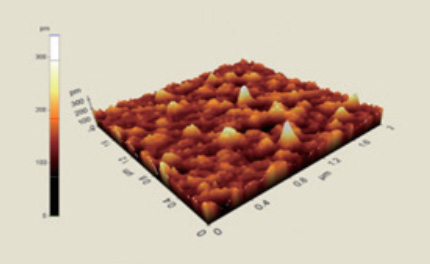

- Arc discharge generates droplets of several μm-sized with ions. If this droplets are included in the thin film, the physical properties such as surface roughness are deteriorated.

- J&L’s FCVA system is equipped with a magnetic filter to completely remove the droplets. FCVA only allows plasma ions to reach the surface of the product, and the thin film coated with this system has excellent properties such as surface roughness.

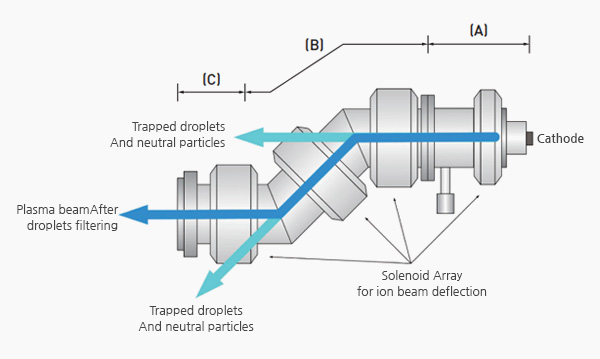

Structure and Principles of FCVA Source

- Arc generating part (A) : Arcing on the surface of the coating material

- Filtering part (B) : Droplet removal and a path for plasma ion passing

- Outlet (C) : Plasma ion beam passing through the filter is deposited on the substrate

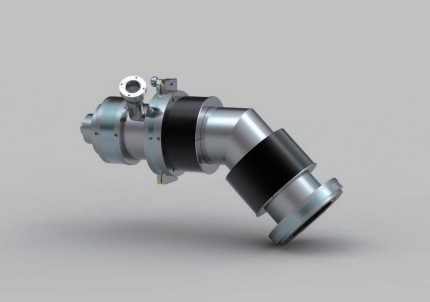

Single bent

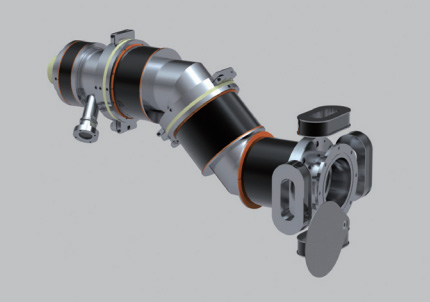

Double bent

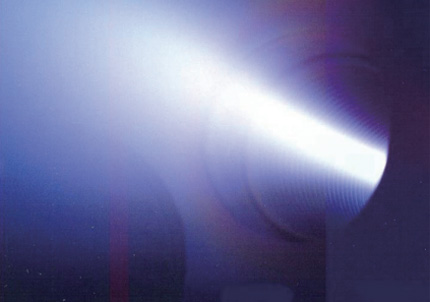

Arc discharge

Characteristics of FCVA Sources

- Droplet removal through dual-bent duct filtering

- Ultra-smooth surface

- Large-area deposition through Beam-Rastering

- Innovative electrode design for stable plasma beam

- High adhesion

- High reproducibility and easy maintenance

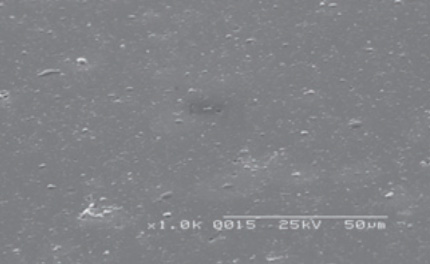

Single-Filtering

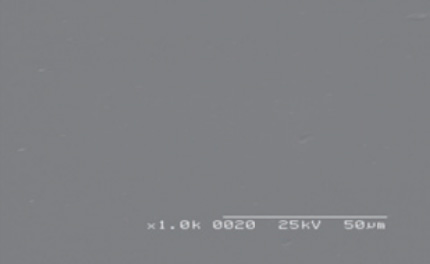

Double-Filtering (Ultra-Smooth)

Scan area : 2x2 um2 , Ra = 0.02 nm

Specification of FCVA Source

| Single Bent | Double Bent | ||

| Cathode | Material of the Target | Graphite | |

| size | ø75 x 25(L) mm | ||

| Duct | size | I.D.ø144mm, O.D.ø165.2mm | |

| Angle | 45° | ||

| Filtration Method | Single | Double | |

| Magnet | Source magnet (SM), Bending magnet (BM), Output magnet(OM), Raster magnet(RM) | Source magnet (SM), Bending magnet (BM), Emission magnet(EM), Output magnet (OM), Raster magnet(RM) | |