HOME / COATING SYSTEM / MERALLION™

MERALLION™

Solutions for various types of metal hard coatings

METALLION™ is a coating system that uses arc discharge to evaporate the metal target of the cathode and deposit it on the surface.

Various metal coatings such as TiN, TiCN, TiAlN, and CrN are available depending on the target used.

All specifications of the system are optimized and provided according to the customer's requirements.

METALLION™ is a coating system that uses arc discharge to evaporate the metal target

of the cathode and deposit it on the surface.

Various metal coatings such as TiN, TiCN, TiAlN, and CrN are available depending on the target used.

All specifications of the system are optimized and provided according to the customer's requirements.

System Specification

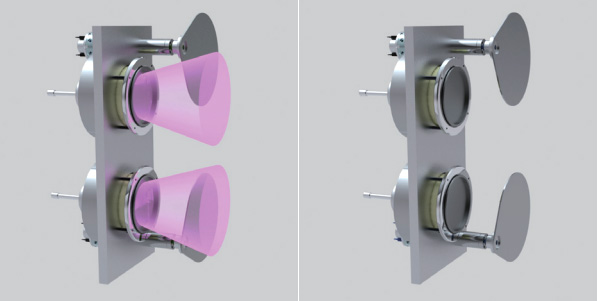

| Plasma Source | 5″ Cathodic Metal Arc Source (Auto trigger, Direct Water Cooling) |

| Chamber Size | Ø600×H600, Ø700×H900, Ø800×H1000, Ø1000×H1000, Ø1000×H1200, Custom-made |

| Jig System | 2 fold or 3 fold |

| Working Gas | Mass flow control system Ar · O2 · N2 · etc |

| The Initial Vaccum Degree | ~10-6Torr |

| Bias Power | Pulsed DC |

| Heater | Max 480℃ |

| Device Operation | Automatic / Semi-automatic |

주요 특징

- 다양한 코팅막 증착이 가능

- 높은 증착률 및 이온화율

- 금속 모재에 대한 우수한 접합력

- 코팅 상대재에 대한 높은 접합력

- 높은 재현성과 유지보수의 용이성

Advantages of Metal Cathodic Arc Source

- A variety of coating materials

- High deposition rate and ionization rate

- Excellent adhesion to metal substrates or coating counterparts

- High adhesion to the substrate

- High reproductivity and easy maintenance

Applications

- By selecting the appropriate target materials, various coatings such as TiN, TiCN, TiAlN, AlTiN and CrN are available.

TiN

TiCN

TiAlN

AlTiN

CrN

Contact us

Applications

- By selecting the appropriate target materials, various coatings such as TiN, TiCN, TiAlN, AlTiN and CrN are available.

TiN

TiCN

TiAlN

AlTiN