HOME / Coating System / CARBOZEN™

CARBOZEN™

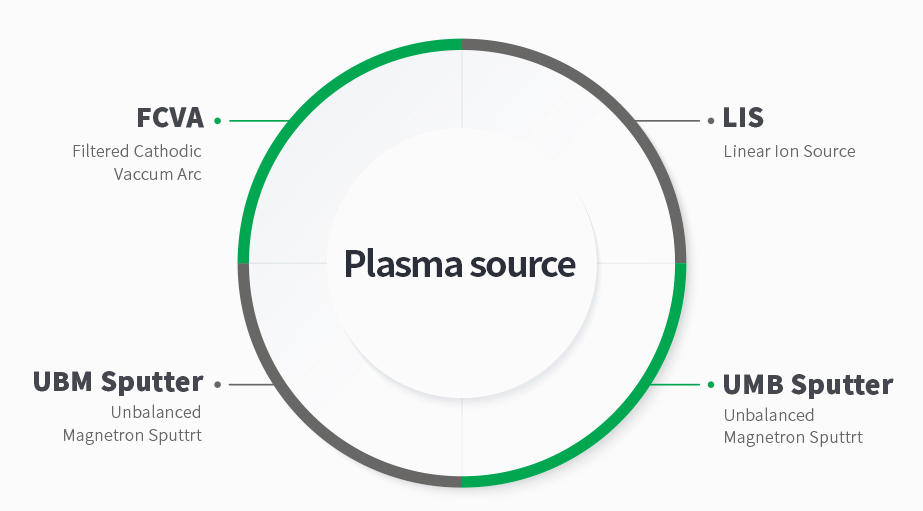

Hybrid coating system combining various plasma sources

We internalize all major plasma technologies from PVD plasma sources such as FCVA (Filtered Cathodic Vacuum Arc),

LIS (Linear Ion Source), and UBM (Unbalanced Magnetron Sputter) sputter to PECVD (Plasma Enhanced CVD).

CARBOZENTM is manufactured by optimizing the combination of plasma sources according to customer requirements.

We internalize all major plasma technologies from PVD plasma sources such as FCVA (Filtered Cathodic Vacuum Arc),

LIS (Linear Ion Source), and UBM (Unbalanced Magnetron Sputter) sputter to PECVD (Plasma Enhanced CVD).

CARBOZENTM is manufactured by optimizing the combination of plasma sources according to customer requirements.

System Specification

| Plasma Source | FCVA (Filtered Cathodic Vacuum Arc) LIS (Linear Ion Source) UBM Sputter (Unbalanced Magnetron Sputter) PECVD (Plasma Enhanced CVD) |

| Chamber Size | Ø600×H600, Ø700×H900, Ø800×H1000, Ø1000×H1000, Ø1000×H1200, Custom-made |

| Jig System | 2 fold or 3 fold |

| Working Gas | Mass flow control system Ar · O2 · C2H2 · CH4 · C6H6 · etc |

| The Initial Vaccum Degree |

~10-6Torr |

| Bias Power | Pulsed DC |

| Heater | Max 250℃ [Optional 450℃] |

| Process | Automatic / Semi-automatic |

Advantages of Linear Ion Source

- Maintaining stable ion energy during coating film deposition

- Uniform coating film formation for large area products

- Low maintenance costs

- High adhesion

- Cleaning using Ar, O2, N2 gas

| Deposition Rate | 300nm/min |

| Residual Stress | ~ 2.0GPa |

| Hardness | ~ 28GPa |

| Friction Coefficient | ~ 0.1 |

| LIS350 | LIS650 | LIS800 | LIS1000 | LIS1200 | |

| Size (mm) | W102 × H380 | W102 × H680 | W102 × H840 | W102 × H1044 | W102 × H1244 |

| Type of Magnet | Permanent magnet | ||||

| Coating effective area | 340mm | 656mm | 790mm | 990mm | 1190mm |

| Coating Uniformity | ± 3% | ||||

| Voltage | 500 ~ 3000V | ||||

| Operative Pressure | 0.7 ~ 3mTorr | ||||

| Source | Ar, N2, O2, C2H2, CH4, etc | ||||

Advantages of UBM Sputter

- Able to use alloys, compounds and insulating layers to deposit thin film

- Enable to various reactive sputtering

- Uniformity of the deposition layer

- Large Sputtering Target Enable

- Low temperature process

- Easy to color coatings of oxide and metal nitride

| UBM350 | UBM650 | UBM850 | UBM1050 | UBM1200 | |

| Size (mm) | W100 × H350 | W100 × H680 | W120 × H850 | W120 × H1050 | W120 × H1200 |

| Type of Magnet | Permanent magnet | ||||

| Coating Uniformity | ± 3% | ||||

| Operative Pressure | < 30mTorr | ||||

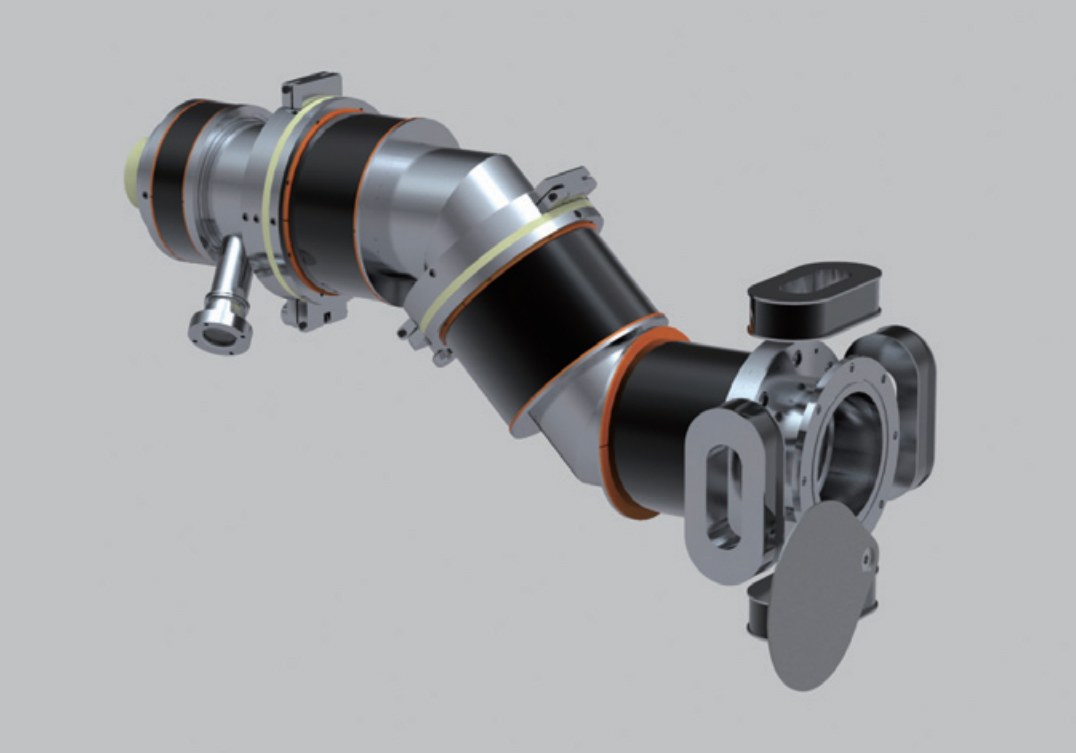

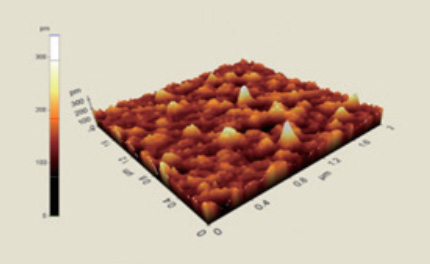

Advantages of FCVA Source

- Droplet removal through dual-bent duct filtering

- Ultra-smooth surface

- Innovative electrode design with increased plasma beam stability

- Innovative electrode design for stable plasma beam

- High adhesion

- High reproducibility and easy maintenance

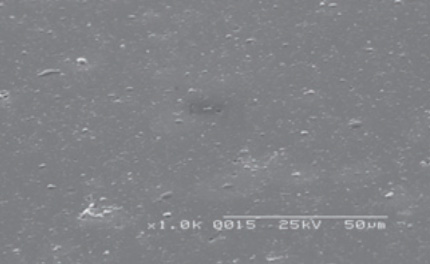

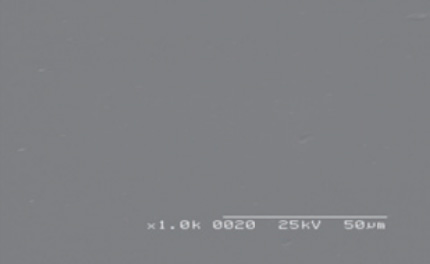

Single-Filtering

Double-Filtering (Ultra-Smooth)

Scan area : 2x2 um2 , Ra = 0.02 nm

FCVA Source Specification

| Single Bent | Double Ben | ||

| Cathode | Material of the Target | Graphite | |

| size | ø75 x 25(L) nm | ||

| Duct | size | I.D.ø144mm, O.D.ø165.2mm | |

| Angle | 45° | ||

| Filtration Method | Single | Double | |

| Magnet | Source magnet (SM), Bending magnet (BM), Output magnet(OM), Raster magnet(RM) |

Source magnet (SM), Bending magnet (BM), Emission magnet(EM), Output magnet (OM), Raster magnet(RM) |

|